Bảo trì tập trung nâng cao độ tin cậy (RCM - RELIABILITY CENTERED MAINTENANCE) là chiến lược bảo trì được ứng dụng phổ biến trong các nhà máy công nghiệp ở các nước trên thế giới.

RELIABILITY CENTERED MAINTENANCE (RCM) is a maintenance strategy commonly used in industrial plants in countries around the world.

With this strategy, resources for maintenance work are optimally used by focusing on items that thoroughly handle existing damage to equipment and systems selectively, based on frequency. how failures and their criticality affect plant-wide reliability, availability, and performance. From there, it helps improve the factory's production productivity, while significantly saving regular maintenance and repair costs.

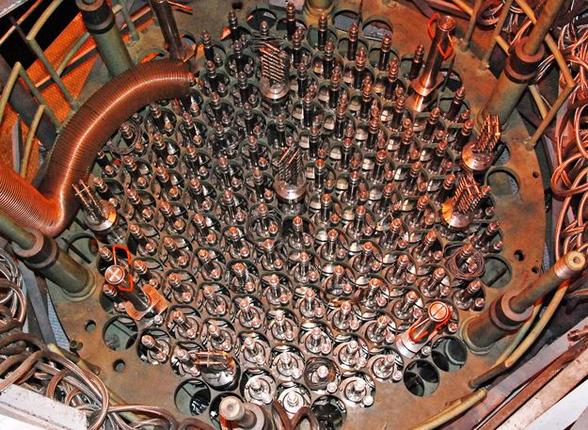

With the superiority of RCM, since 2016, EPS has conducted research to apply this solution to large capacity power plants in Power Generation Corporation 3. The most obvious is the 5 technology solution package project. Improving the reliability and operational efficiency of Vinh Tan 2 power plant (capacity 1244 MW) including:

- Install a system to monitor the life of important details in the boiler

- Optimize the control process of combustion technology processes in the furnace

- Optimize main steam temperature entering the turbine

- Optimize the boiler dust blowing process

- Replace the air dryer's leaky air seal

Vinh Tan 2 Power Plant is one of the units that successfully applied the RCM maintenance strategy provided by EPS.

As a result, after implementing the above 5 solution packages, the efficiency of Vinh Tan 2 Power Plant increased by 1.8% compared to before, while significantly improving the ability to optimally control furnace operating parameters. steam, steam turbine. From there, we can reduce subjective incidents caused by humans to the boilers of the power units, ensuring safe, continuous and stable operation of the power units.

Mr. Truong Van Phuong - Deputy Technical Director of EPS Company affirmed: "The success of 5 solution packages to improve reliability and operational efficiency at Vinh Tan 2 Thermal Power Plant shows that EPS has applied effectively The maintenance strategy focuses on improving reliability, while adopting calibration technology, monitoring boiler life status, and measuring the performance of large-capacity coal-fired power plants."

In 2018, EPS continues to coordinate with domestic power generation companies, ready to support awareness training on the superiority of focused maintenance strategies to improve the reliability of plant systems and equipment. , as well as consulting on technical solutions and implementation methods based on the operating status, reliability and availability according to the actual conditions of the Plant.

EPS Company